Specifications: (Source: Testometric Company Ltd)

| XFS100 | |

| Force kN | 100 |

| Accuracy | Better than +/- 0.5% read down |

| up to 1/1000 capacity force sensing capacity | |

| Cross stroke mm * | 1100 |

| Vertical space mm * | 1400 |

| Position control resolution mm | 0,00001 |

| Spacing between columns mm * | 480 |

| Minimum speed mm/min | 0,00001 |

| Max speed mm/min | 600 |

| Precise speed | +/- 0.1% under stable condition |

| Maximum force at top speed kN | 100 |

| Maximum speed at full load mm/min | 600 |

| Crawl Rate (on PC) | 500 Hz as standard (1000 Hz optional) |

| PC connection | Ethernet (or USB via adapter) |

| Configuration | Double column, floor stand with |

| diagonally opposite ball screw and guide rod | |

| Frame stiffness kN/mm | 500 |

| Weight / kg | 940 |

| Operating temperature °C | 0 to +55 |

| Active humidity | Relative humidity 90% or less |

| Power supply | 3 phase 380/400 V |

| Power kW | 2,2 |

Made to measure

The XFS100 Versatile Tester is a complete digital test system with high controllability and accuracy. It allows the computer to automatically control the testing techniques allowing for ease of operation.

High resolution force sensor with accuracy higher than +/- 0.5%, as low as 1/1000 capacity of force sensor

Automatic detection of extensometers and force sensors, along with on-board storage of calibration parameters

Software calibration test facility allows instant verification of machine accuracy

Capable of 800% overload of force sensor without any kind of damage

Highly efficient, self-cleaning, pre-loaded ball screws allow for quick and quiet inspection; equipped with end bearings that are lubricated for life

Overcharge, Overload and Impact Protection

Integrated force-sensing cable routing included in the mast prevents breakdowns and avoids cable damage

Horizontal line guide system ensures smooth operation and allows precise alignment

Small area design ensures economy of floor space

Precise crosshead control via brushless servo motor and digital AC servo drive enables 23-bit position control and maintenance-free operation

High-speed data acquisition system provides up to four sync channels

Includes six I/O channels for additional devices, like calipers, micrometers, balances, extenders, and more.

Includes a wide range of contact and non-contact extenders

High rigidity load frame supplied with precision ground gauge 50 mm diameter steel guides as well as rigid extrusion support columns equipped with T-slots available for mounting accessories

Telescopic cover provides extra safety for ball screws from dust and test debris

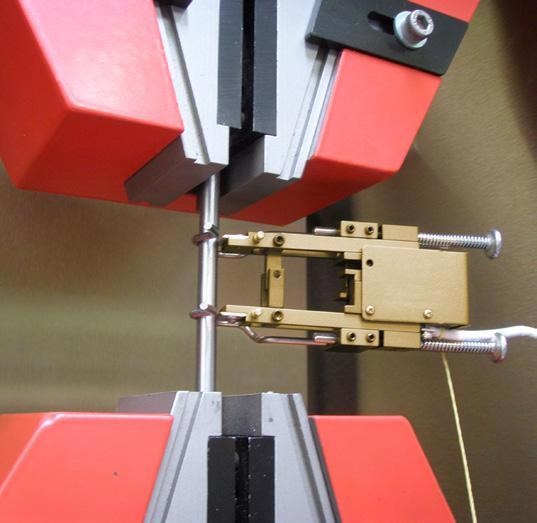

Various clamps and fixings are available for compression, tensioning, cutting, peeling, bending, product testing, and more.

(1) Available at additional cost. Alternatively, the machine can be controlled using a standard PC or laptop (not supplied). (2) Machine with heavy duty hydraulic handle HG300 (sold separately). Image credit: Testometric Company Ltd

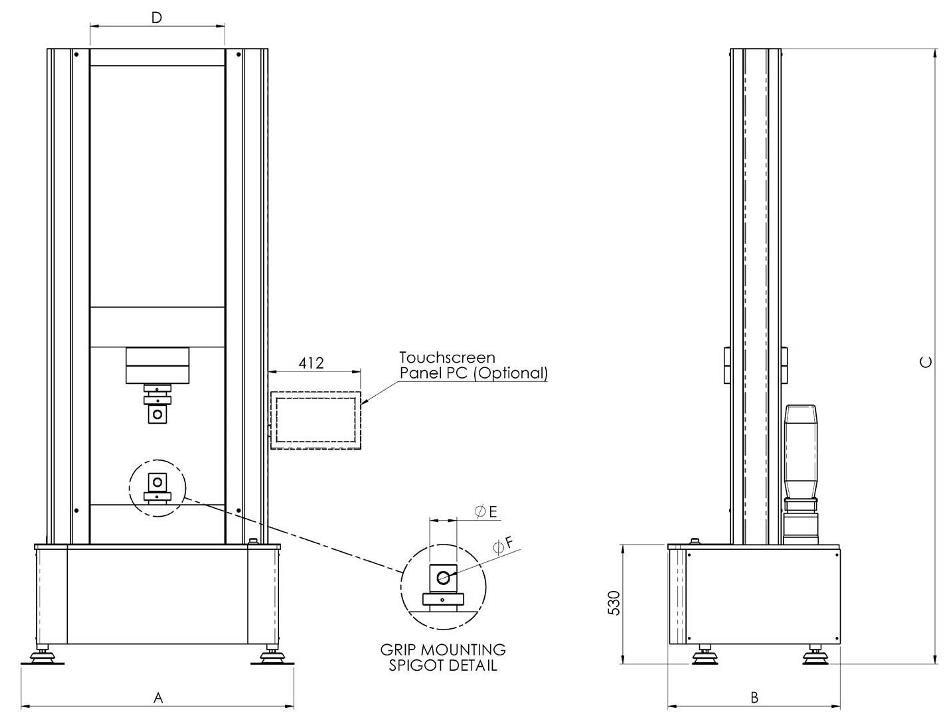

XFS Size

Image credits:Testometric Company Ltd

Table 2. Source: Testometric Company Ltd

| XFS100 | |

|---|---|

| Overall Width ‘A’ (excluding touch screen) | 1070 |

| Depth ‘B’ | 765 |

| Overall height ‘C’ | 2300 |

| Spacing between columns ‘D’ | 480 |

| Spigot Ø E | 40 |

| Spigot Pin Ø F | 16 |

Note: All dimensions are in millimeters. Dimensions are based on standard models and extended/wide frame versions are available upon request.

Fully extended measuring range. Image credit: Testometric Company Ltd

Built for precision

Measure force

Better than specifications EN 7500-11 Level 0.5; conforms to DIN 51221, ASTM E-4 and AFNOR A03-501 standards; globally calibrated; provide minimum range from 0.4% to 100%; automatic identification of the force sensor; electronic force sensor protection; whose resolution is 1 part in 50000.

Extended Measurement

This covers the full frame length to the highest resolution of 0.0001 mm (selectable), offers +/− 0.01 mm accuracy, and includes relative, absolute and relative modes. relative and auxiliary in inches, mm and percent.

Speed control

Offers best-in-class low-speed performance with speeds down to 0.00001 mm/min. Temperature and current protection of the drive system is available.

Load frame

This is a rigid frame, using a rigid extruded support column and precision grounded steel guides. Frame stiffness up to 2000 kN/mm plus built-in K-factor. Other features include a return ball screw with bellows, total travel, electronically limited travel and customer-programmed safety stops.

Electronic system

The modular electronics system enables rapid data transmission to the computer (up to 1000Hz) via a high-speed Ethernet connection. Comprehensive input options allow connection of a wide range of accessories and extensometers through easy plug-in interface modules.

Safety Features

Complex safety features ensure the highest level of operator safety, such as programmable extension limits, E-Stop, overload and impact detection. Fully compliant with general safety directives, such as Machinery Directive 2006/42/EU, Low Voltage Directive 2014/35/EU and Electromagnetic Compatibility Directive 2014/30/EU.

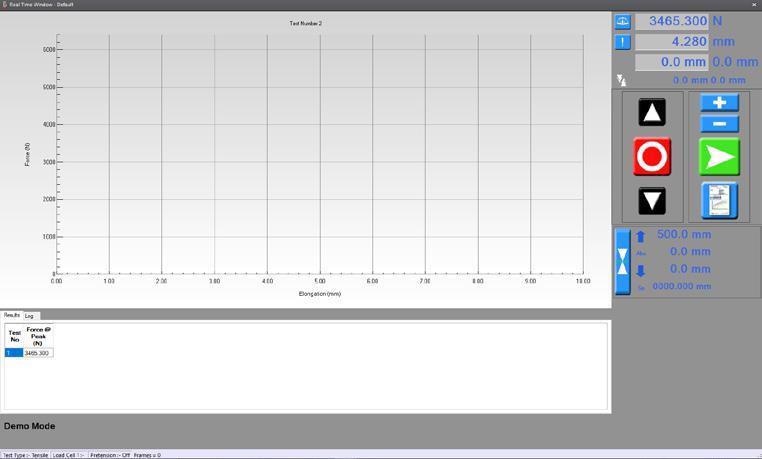

Optional touch screen control tablet

When combined with the optional IPC3 industrial-grade Panel computer with touch screen control, it turns into a rugged, standalone system without the need for a laptop or external computer.

Running the complete version of Testometric’s winTest software and using the advanced Windows 10 operating system, the system allows complete control of the test machine, while providing storage and access to methods and Unlimited test results.

The integrated mounting arm, fixed to the machine’s T-Slots column, is fully adjustable for reach, height and viewing angle, allowing the user to determine the most convenient working position.

Screen specs:

15.6-inch 1366 x 768-panel resistive touch screen with dustproof, anti-reflective screen protector

Chipset QM87, 4 x USB3.0, 3 x COM ports [RS232] and 2 x GigaLAN

2.5 inch 250 GB, Solid State Disk (SSD) and SATA III 6 GB/s

CPU-i5-4300M Intel Core i5 processor, 2.6 GHz.

4 GB, 1600 MHz DDR3 204-pin SODIMM

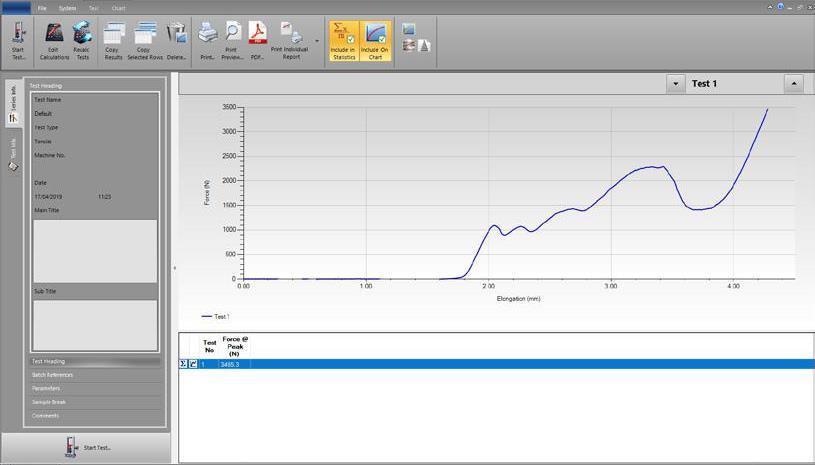

Tried and tested software

All Testometric models are supplied with Testometric’s comprehensive winTest Analysis software package.

The winTest Analysis software package is the product of years of continuous development, providing an intuitive and flexible package to suit all types of material testing. Integrated test methods include tensile, shear, shear, compression, circulation, bending, tear, creep and multi-stage tests.

The software includes a wide range of industry standard test methods and the ability to create and store an unlimited number of other test techniques. All inspection data is automatically stored and can be easily exported to other software packages, such as Excel, Word, Access and SPC systems to improve report generation.

By adding the RCE remote connection option, all machines can be web-linked directly to Testometric for remote analysis, monitoring and software upgrades.

Real-time test screen. Image credit: Testometric Company Ltd

Test analysis screen. Image credit: Testometric Company Ltd

Reviews

There are no reviews yet.